With the development of automation technology, the Internet of Things, and artificial intelligence, an increasing number of manufacturing industries are adopting smart factory solutions to gain real-time control of production and sales processes, improve production controllability, eliminate information silos, and ultimately achieve precise and efficient production planning, scheduling, inventory, and quality management. In the traditional glass processing industry, as the demographic dividend fades, the incremental market shrinks, and market competition intensifies, only those enterprises with advantages in quality, efficiency, and comprehensive costs can cope with challenges and seek development. In the following case study, we will analyze the many advantages brought by smart factories in terms of efficiency, energy consumption, labor, and other aspects, providing a reference for your enterprise's development planning.

Modern Zhumei Glass is affiliated with Modern Zhumei Home Furnishing Co., Ltd., a subsidiary of Country Garden, and is the first smart factory in China to achieve the intelligent production of shower screen glass. We will analyze two important efficiency indicators of this smart factory:

1. Efficiency improvement

In traditional glass processing factories, workers seem busy, but the overall efficiency is low. The key lies in the low efficiency of manual labor, which lowers machine performance. Meanwhile, unreasonable production organization and coordination also lead to low overall efficiency. In ZhuMei's smart factory, only three digital operators are needed, each responsible for multiple machines, requiring no intervention during normal production. A shift can produce 1,200 pieces of shower glass, allowing the machine to operate at its best efficiency. Meanwhile, the smart factory uses ERP and MES systems to monitor and provide real-time feedback on production status, thereby reasonably coordinating production.

2. Reduction in labor

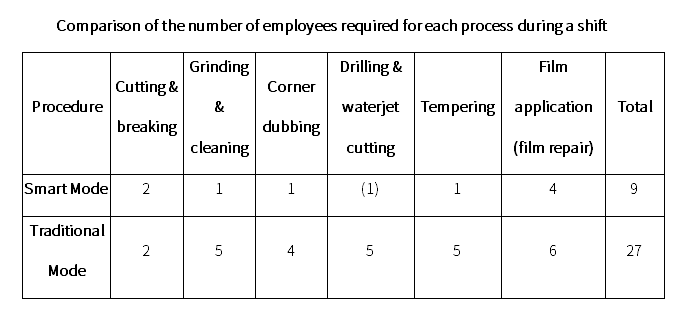

In ZhuMei's smart factory, repetitive physical laborers such as glass handlers have been significantly reduced, not only lowering the company's labor costs but also reducing the risk of work-related injuries. The specific data is as follows:

As shown in the table, a production shift can save labor by: 27 – 9 = 18 people; with an average annual salary of 72,000 CNY/person, the annual savings in labor costs for one production shift are: 18 * 72 = 1,296,000 CNY. Moreover, in the smart factory, the contact between people and glass, glass and glass, and glass and transfer racks is greatly reduced, thus avoiding scratches and stains and ensuring product quality.

In recent years, LandGlass smart factory team has successfully delivered several complete smart factory projects. LandGlass team will be waiting for your visit and discussing the changes and opportunities brought by intelligent manufacturing to the glass processing industry!